Our Filtration services

Filtration solutions made to order by FILTRACON®

FILTRACON® provides individual filtration solutions for industry – whether for oil mist, smoke or dust, our expertise in keeping air clean means that you have found the right partner in us.

Whatever the characteristics that your filtration system must have and whatever environmental factors it must be able to withstand, FILTRACON® develops the right solution, precisely tailored to your needs and expectations.

Oil & emulsion mist separators

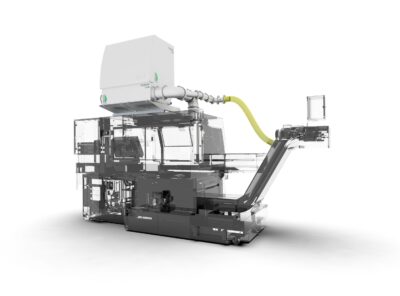

Cooling lubricants such as emulsions and oils are often used for machining work. If these make contact with a rotating spindle or rotating workpiece, a fine mist is created. The mist can enter the atmosphere through the various openings in a tool machine. This is damaging not only to the environment, but also to your employees and machines. The mist is respirable and alveolar, and can cause conditions such as skin irritations and retinal inflammation, thereby damaging the health of your employees. The mist can clog up machines severely, in particular electrical components and measuring instruments, there fore impairs their function. As the mist also settles on the floor, the working environment becomes unsafe and maintenance costs are high. By means of controlled ventilation of the machining volume of a tool machine using our extraction systems, the contamination can be separated out and the treated air released into the atmosphere. Our extraction systems protect your employees, increase the availability and service life of your machines, protect your building, and,last but not least, safeguard the environment.

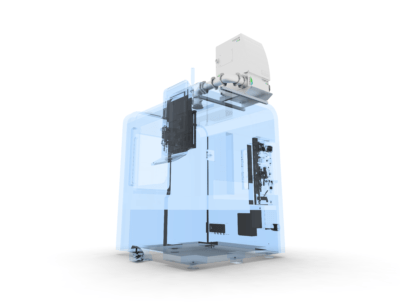

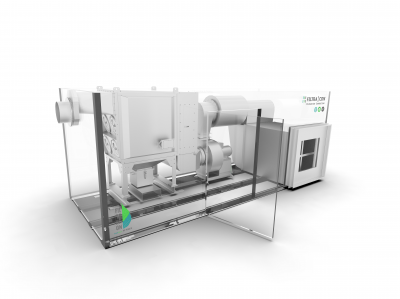

Directly fitted oil mist separators are suitable both for small and medium-sized tool machines as well as for small group extraction systems. The extraction capacity varies between 300 and 2,500 m³/h. They are usually installed directly onto the roof of the machine, so no additional space is required in the production hall.

Dust & smoke separators

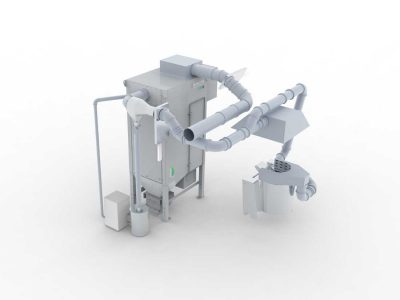

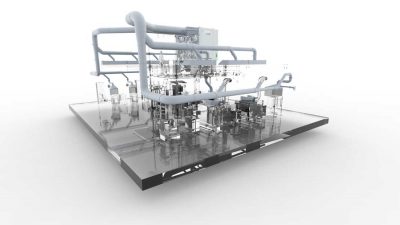

Where there is planing, shavings fall, where there is sanding, dust is created, and where welding or pouring occurs, smoke. Dust and smoke separators ensure that certain processes are made possible in the first place. The wide variety of different separation technologies provides the right solution for every application. The systems can be supplemented with pre-separators, post-filter systems, explosion relief and suppression or extinguishing systems.

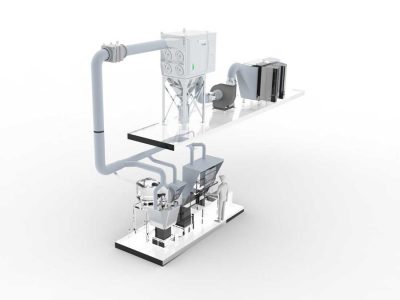

“Plug and play” is the motto here. Compact dust extraction systems are positioned, connected to the pipe network and switched on. They process volume flows of up to 5,000 m³/h and are suitable for a wide range of applications thanks to the flexible options as far as filter technology, pre-separators, after-filtration and equipment for explosive mixtures of dust are concerned.

Perfect for anyone who has little available space or simply wants to save space – solid material separators with cartridges offer a large filter surface area in the smallest of spaces. Thanks to modern filter media, very high separation performance can be achieved and they are incredibly flexible, as the systems can be combined in any way. Of course, these systems are also suitable for explosive mixtures of dust. The safety of the machines can be ensured by including non-return valves, bursting discs, extinguishing systems and suppression systems.

Filter systems that are equipped with filter hoses or filter bags are able to cope with large volumes of airflow. They are popular for agglomerative dusts and can be adapted to many applications by the addition of a wide range of textile filter media. Extensions including pre-separators, rotary valves as discharging devices and an after-filter stage are possible. With the right accessories, these systems can also deal with explosive dusts.

Wet scrubbers and wet separators are ideal for solid materials that can only be treated with difficulty by a dry separator, if at all.

This separation principle has proved itself in particular with damp and sticky substances and dusts that are contaminated with cooling lubricants. Wet scrubbers are also suitable for hot, sparking and glowing particles and flammable and explosive dusts.

Gas & air cleaning

Air can also be contaminated with non solid materials. Dirty air can smell unpleasant and even irritate the airways, nose, skin and eyes if it contains caustic gases. Gas and air cleaning systems capture scent molecules and wash out gases. Gas and air cleaning systems can either treat room air in general or they can be connected directly to the source. Either way, they create a pleasant and safe working environment for your employees and protect your environment.

These systems are particularly suitable for treating ambient air with normal or little contamination. They are characterized by low pressure loss and can be operated passively, i.e. without compressed air or a washing system. As these systems capture the solid materials (storage filters), the pressure loss increases over time. When the pressure differential limit is reached, the filter inserts can simply be replaced.

An air volume that is heavily contaminated with odors or volatile substances can be treated effectively with a blend of active carbon adapted to the application. The contaminant is concentrated in the active carbon. Active carbon mainly consists of carbon with a highly porous structure. The pores are interconnected as they are in a sponge.

Did you know that the internal surface area of 2 grams of active carbon roughly corresponds to the area of a football field? Wussten Sie, dass die innere Oberfläche von 2 Gramm Aktivkohle in etwa der Fläche eines Fussballfeldes entspricht?

Gas scrubbers are used in processes in which exhaust gases are created that are harmful to health and/or are not permitted to escape into the atmosphere. Exhaust gas scrubbers can be set up in either a vertical or horizontal arrangement. Depending on the application, the washing liquid is enriched with chemical additives that allow optimal absorption of the contaminants.

FILTRACON Anti Virus Air Cleaner

FILTRACONs AVAC-Systems. Tested and approved!Efficient Control of Aerosols

According to the latest scientific report from the World Health Organization on the transmission of SARS-CoV-2, there is overwhelming evidence that aerosols play an important, if not decisive, role in the spread of the SARSCoV-2 virus. In general, quite apart from the ubiquitous discussion about the SARS-CoV-2 virus, air filters are the method of choice for the efficient removal of viruses due to their ability to control aerosol levels in the air. This has been researched for years and has been proven by numerous studies.

The Conclusion: The control or containment of aerosols by means of efficient filtration is synonymous with the containment of the viral load in the air, which consequently leads to a reduced risk of COVID19 infections.

This paper is intended to contribute to a better understanding of aerosols and their properties, as well as providing explanations that show, that the right filter-choice is crucial for reducing the risk of infection due to virus-laden air.

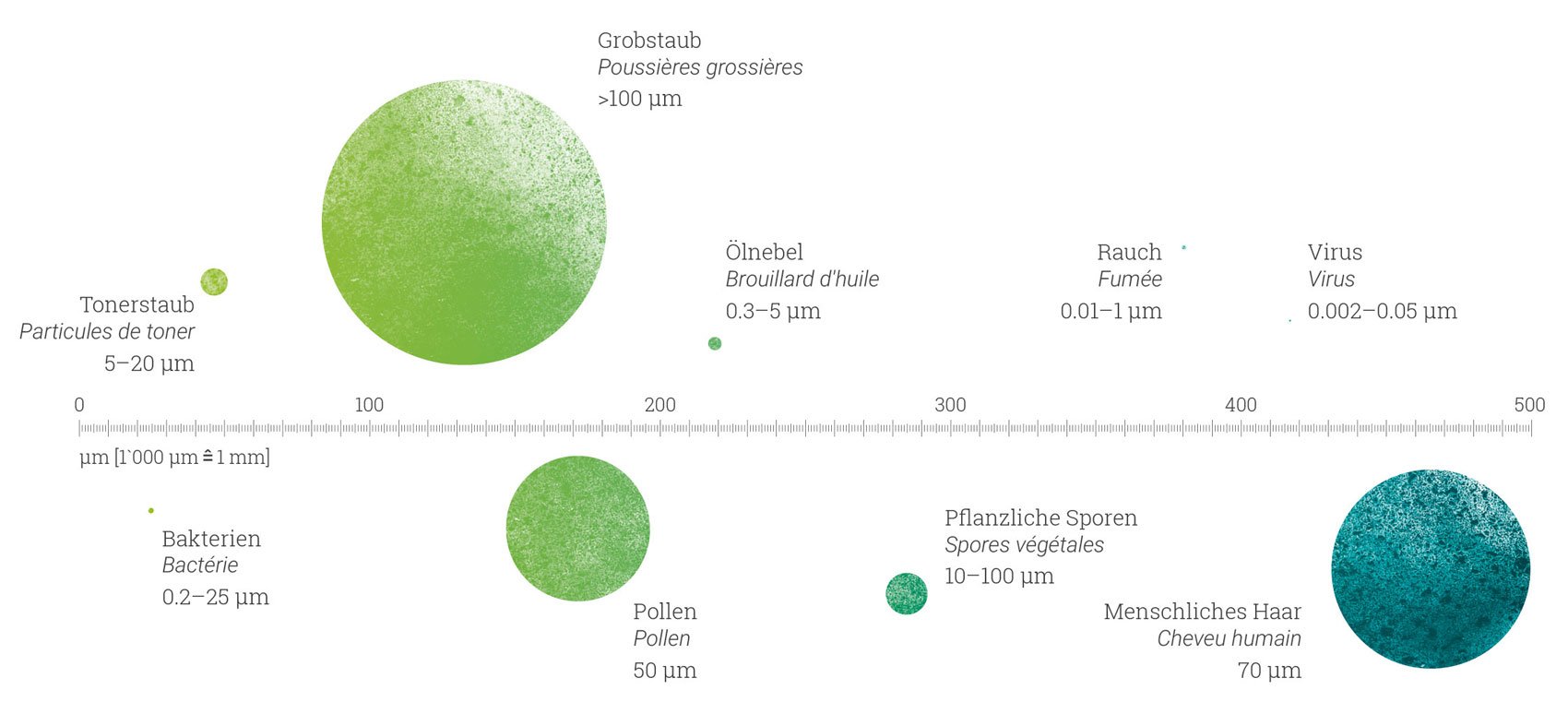

Characteristics of Aerosols

Generally, an aerosol is defined as a suspension system of solid or liquid particles in a gas. An aerosol includes both the particles and the suspending gas, which is usually air. Aerosols are typically classified according to their physical form and how they were generated. Fume, mist, smoke, smog, diesel soot or fog are typical examples. The diameter of aerosol particles is in the order of magnitude between 0,01 μm and 10 μm. Particle size is often determined by the process that generated the particle. For example, combustion particles usually start out in the 0,01-0,05 μm size range, but are likely to combine with each other (agglomerate) to form larger particles. Individual aerosol particles are therefore not visible to the naked eye. A quantity of aerosol particles in air is only visible, depending on the particle size, from concentrations of 10.000 to 100.000 particles per cubic centimeter. All accumulations of aerosols in the air to which fungi, bacteria, pollen or viruses adhere are called bioaerosols.

Aerosols, to which a virus such as the SARS-CoV-2 virus is bound, must therefore correctly be called bioaerosols.

How exactly the corona virus is spread – whether primarily via a droplet infection or rather via aerosols in the air we breathe, is currently intensively researched. When a corona patient coughs, speaks, or sneezes, a jet of droplets and aerosols of different sizes is created, which then penetrates the room air. All of these different sized droplets and aerosols potentially contain viruses, because viruses tend to stick to larger particles.

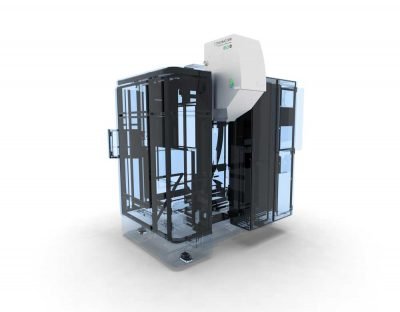

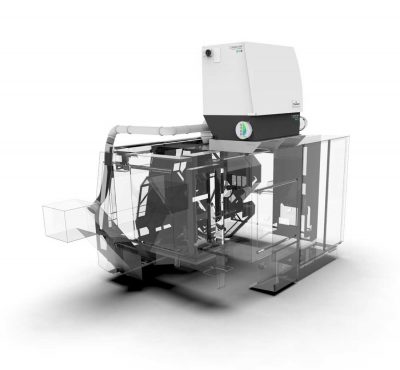

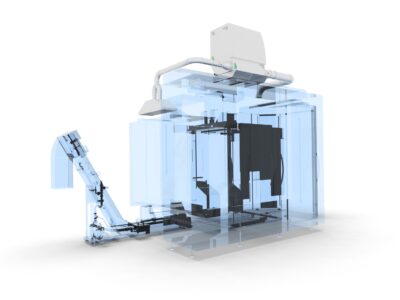

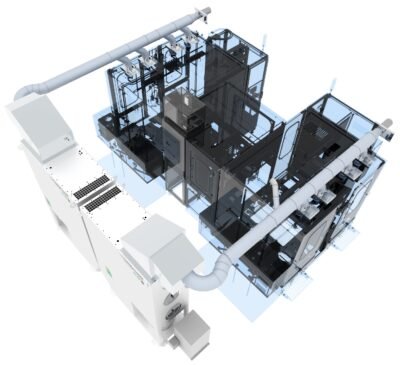

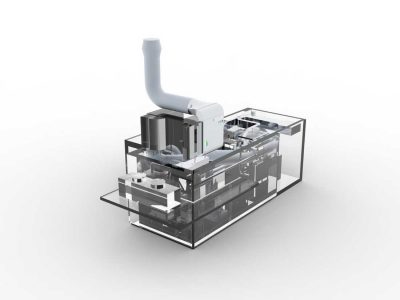

FILTRACONs AVAC-Systems are totally self-contained stand-alone Recirculation Units for areas where additional, extra high filtration performance is needed against any type of contamination including viruses. FILTRACONs AVAC-Systems combine state-of-the-art HEPA filtration with UV germicidal irradiation to create total clean air solutions fulfilling all relevant guidelines. There are two expansion stages available.

FILTRACONs AVAC-PS2000 – best choice for public spaces

Thanks to the insulated double-wall constructions leading to whisper-quiet operation, it is ideally suitable for indoor use in for example offices, schools, health care facilities or hotel lobbies, just to name a few.

FILTRACONs AVAC-FW4000 – best choice for factory workshops

This is the heavy duty version of the PS 2000 which provides up to double air flow (4'000 m³/h). There is an exhaust box with integrated jet nozzles mounted on top of the AVAC-FW 4000. This enhances the throwing distance of the clean air.

Features & Benefits

- Suitable for indoor use

- Combines HEPA filters and UV germicidal irradiation

- Designed with internal variable speed fan (electronically commutated)

- filter combinations to meet specific application requirements

- Whisper-quiet operation

- Totally self-contained system

- Easy to install, operate and maintain

- CE-compliance

Plug & Play Design

To allow economical and easy installation, FILTRACONs AVAC-Systems are designed as a Plug & Play unit, hence no modifications are required at your premises. Simply install the selected FILTRACON AVAC-System and dispose it when no longer effective. Maintaining the unit is as easy as the installation itself. The sliding tray design provides easy access to and servicing of the fan. The instrument panel provides easy access and servicing of gauges, disconnect, and speed control.

Technical data

Airflow: 50 - 2'000 m³/h

Dimensions: 770 x 720 x 1'628

Fan: 0.5 kW - 1 Ph - 230 V - 50 Hz

UV Power: 25 W

Sound level: 35 - 52 dB

Weight: 150 kg

Control: Airflow adjustment, Touch screen

Technical data

Airflow: 500 - 4'000 m³/h

Dimensions: 1'000 x 900 x 2'690

Fan: 3.0 kW - 3 Ph - 380 V - 50 Hz

UV Power: 200 W

Sound level: 65 - 72 dB

Weight: 800 kg

Control: Airflow adjustment, Touch screen

Accessories

Here you will find the right suction arm, a new filter control system, cleaning valves or complete pressure tanks.

The filter controls RM-208 C / ... CB and RM-216 C / ... CB from the EasyLine series are controllers with a loop bus interface for controlling the extension modules RM-LV8 / ... 16 for the robust, industrial use on filter systems with pulse cleaning with up to 128 valves.

Membrane valve

Membrane valves for use in filtration systems with pressurized pulsing filtration are characterized by very dramatic rises in pressure, a high flow coefficient, and short closing time. These demands are optimally met through a new power reflex membrane. Membrane valves are available for various applications in perpendicular membrane valve, through valve, or valve module variations.

Through Magnet Valve

The development of effective magnet valves as a coupler module between the control electronics and mechanical part of the membrane valve is essential to the realization of shorter reaction times and effective opening time of the membrane valve.

Flushing Gas Tank Systems

FILTRACON® Passive Flame Deflector

The FILTRACON® flame deflector is designed to protect separators on machine tools from the effects of possible flames.

FILTRASLIDE

Climate calculator

FILTRASIZER

Filter design in no time

Consumables

As a specialist in the filtration of air and gases from industrial processes, we offer you a broad-reaching product line of filter elements. Here you will find the right replacement filter for cartridge dust removal systems with pulse jet or vibrating unit.

For bag and bag filters with Pulse Jet, Reverse Air or vibrators, you can find the right spare parts here

Venturis

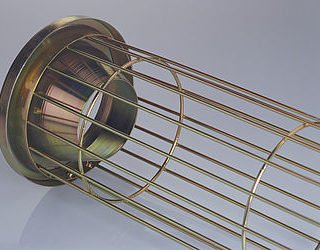

Supporting cages

Supporting cages, venturis

FILTRACOAT

Pre-conditioning of filter elements