Website and corporate design relaunch

5 December 2018

New strong brand: we now also offer extraction arms from FUMEX

28 May 2019Mission accomplished: clean and healthy air in the print shop

Ink mist can be found in almost every press room – and is therefore not without issues, not only for the technical equipment, but above all for the employees.

The performance of offset printing machines is continuously increasing. However, this also increases the problem of ink mist in the printing rooms caused by the high printing speeds. Countless tiny ink droplets are released from the roller during the printing process in the higher performance range and enter the areas around printing presses. Humans and machinery are therefore subject to unwanted levels of exposure – and even more so when using UV ink.

Mechanical engineers have not yet been able to cope with this explosive issue. Many printing facilities have not even recognised it yet. Unlike Benni Wolfensberger from J. E. Wolfensberger AG in Birmensdorf. He refused to leave his employees in the mist.

Load reduced by a factor of 30 – thanks to FILTRACON®‘s solution

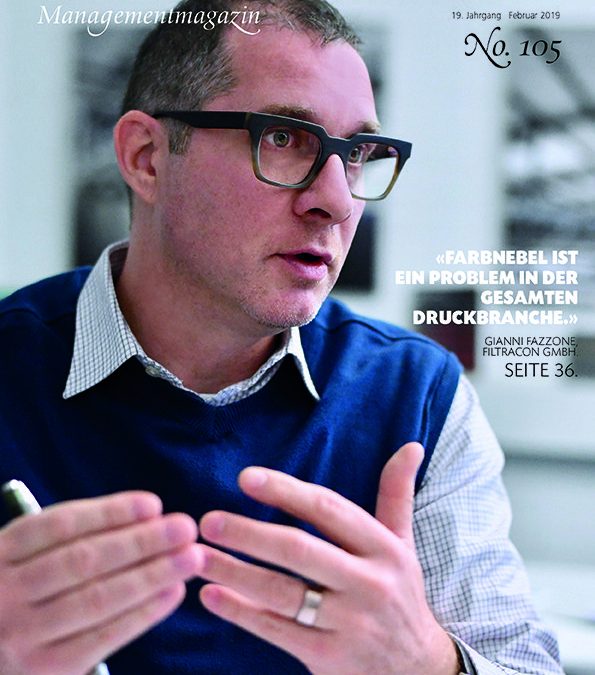

Wolfensberger’s target: Protect employees. But how? Run the machines more slowly? Stop them every few days and go through the costly process of changing filter mats? Not convincing. FILTRACON® had the best solution and even made it to the cover of the magazine “Druckmarkt”: extracting the ink mist by suction at its source at the press roller. Since late summer 2018, our tailor-made plant has reduced the level of exposure by as much as 30 times. Gianni Fazzone, the founder of FILTRACON®, carried out the tests and calculations with state-of-the-art equipment. “If you calculate everything thoroughly, the investment should pay for itself within a year”, said a satisfied Benni Wolfensberger.

You can read the whole article about our first project in the graphic arts industry starting on page 36 of Druckmarkt magazine: http://www.druckmarkt-schweiz.com/index.php?Pos=202&NavPos=20&SPos=10&Heft=105

What challenge do you face? Contact us.